16 Mar iba Stop Cleaning

On March 16, Karl Thorson, Global Food Safety & Sanitation Manager, General Mills, offered iba Connecting Experts attendees best practices to minimize the impact of sanitation.

“Are you in the cleaning business?”

Acknowledging that no one in the food industry is making a profit by cleaning, Karl offered ways manufacturers can minimize cleaning in order to spend more time producing product for customers. Through the observation of an optimal sanitation process, manufacturers can generate cost savings and increased capacity while driving down food safety risk.

Four Steps

- Focus on Labor Reduction

Labor reduction begins by simplifying downtime activities to a calculation of downtime labor minutes/unit of operation. Systems of cleaning, inspection and maintenance need to be designed to reduce the time involved and the number of people in the tasks in addition to minimizing impact and the skills needed for the task.

- Define Clean Success Criteria

Reasons to clean include food safety, human safety, quality, regulatory and operational needs – all requiring different rigor around the tasks. Team with cross-functional and external partners to create clear standards of clean for each and minimize impacts by tweaking equipment design.

- Design Out Labor and Complexity of the Design

Focus on improving the efficiencies of cleaning to drive a step change. The ideal design could reduce labor, and there is a long-term benefit to working with design engineers to minimize the complexities of cleaning by reducing surface area or the number of parts. Creating solutions that make equipment easier to take apart and reduce the number of staff needed for cleaning saves time and resources for other tasks, including inspection and maintenance.

- Provide Access

Access is one of the most critical aspects of design and can directly impact human safety. True access includes the ability to see and touch all the components of any design for easy cleaning and maintenance.

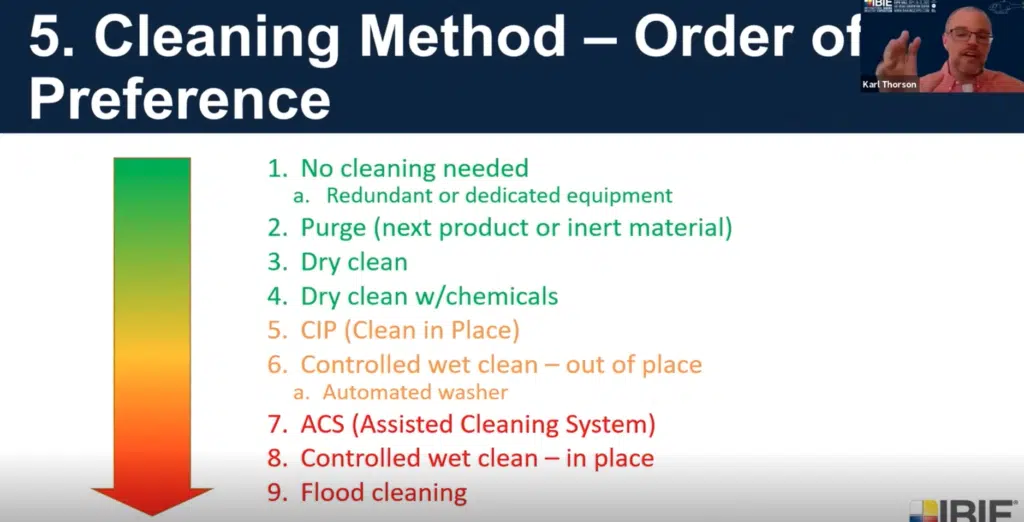

Hierarchy of Dry to Wet Cleaning

- Stability through redundancy, dedicated equipment and complete physical isolation

- Purge or push the product through or use an inert material (salt)

- Dry cleaning (brushing, vacuuming or the use of chemicals) to remove soils

- Clean-in-place (CIP), a controlled, wet clean

- Clean-out-of-place with an automated washer

- Assisted cleaning with water

- Controlled CIP ( bucket, brush or wipe-down) and spreading cleaning products

Whenever possible, avoid the use of water and choose a dry cleaning, less-invasive method, Karl advised. And always optimize cleaning by matching the method to the design of the equipment.

About iba Connecting Experts

Taking place March 15-17, the iba Connecting Experts lecture series offers baking industry professionals and their suppliers a global business platform. The three-day kickoff event offers opportunity for connection, discovery, learning and entertainment and will be followed by a subsequent on-site round of business when iba opens its doors live in Munich on Oct. 2021.

No Comments